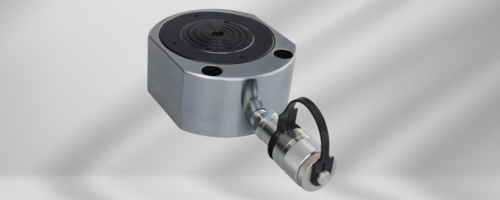

Hydraulic Hollow Ram Jacks Plain Ram, Single Acting

Product Details:

- Flow Rate Depends on manual pump used, typically 0.5-5 LPM

- Operating Pressure 700 bar (10,000 psi)

- Application Pressing, pulling, testing, maintenance, construction, heavy lifting

- Connectivity Type Hydraulic Coupling

- Power Source Manual Hydraulic Pump

- Accessories Coupler, Dust Cap, Manual Hand Pump, Pressure Gauge

- Mounting Type Base Mount / Threaded Collar

- Click to View more

Hydraulic Hollow Ram Jacks Plain Ram, Single Acting Price And Quantity

- 40000 INR/Piece

- 35000.00 - 40000.00 INR/Piece

- 1 Piece

- Rockwell 5055 HRC

- Spring Return

- 50 mm to 150 mm (model dependent)

- Varies from 25 mm to 60 mm

- Chrome plating/Anti-corrosive finish

- Built-in safety valve

- Manufactured as per DIN and ISO standards

- Ranges from 8 kg to 25 kg (model dependent)

- Yellow / Black (Standard)

- Provided on body for easy mounting

Hydraulic Hollow Ram Jacks Plain Ram, Single Acting Product Specifications

- Pressing, pulling, testing, maintenance, construction, heavy lifting

- Hydraulic Coupling

- Manual Hydraulic Pump

- 700 bar (10,000 psi)

- Depends on manual pump used, typically 0.5-5 LPM

- Up to 50 ton (varies by model)

- Coupler, Dust Cap, Manual Hand Pump, Pressure Gauge

- Plain Ram, Hollow Ram, Single Acting

- Base Mount / Threaded Collar

- Manual Hydraulic (Non-electric)

- Hydraulic Cylinder, Hollow Plunger

- Hollow center for versatile applications, corrosion resistant finish, replaceable seals, precision machined plunger

- High mechanical efficiency, over 85%

- -20C to +70C

- High-pressure seals (Polyurethane / Nitrile)

- High-grade Alloy Steel

- Controlled by oil flow, typically up to 10 mm/sec

- Rockwell 5055 HRC

- Spring Return

- 50 mm to 150 mm (model dependent)

- Varies from 25 mm to 60 mm

- Chrome plating/Anti-corrosive finish

- Built-in safety valve

- Manufactured as per DIN and ISO standards

- Ranges from 8 kg to 25 kg (model dependent)

- Yellow / Black (Standard)

- Provided on body for easy mounting

Product Description

Capacity 10 - 100 ton / Stroke 50 - 150 mm / Max. Working Pressure 700 bar

| Capacity (ton) |

Capacity (kN) |

Stroke (mm) |

Model | Effective area (cm2) |

Oil cap. (cc) |

Closed height (mm) |

Wt. (Approx.) (kg) |

|---|---|---|---|---|---|---|---|

| 10 | 110 | 50 | OSH 10-50 | 15.7 | 79 | 150 | 3.7 |

| 10 | 110 | 75 | OSH 10-75 | 15.7 | 118 | 175 | 4.2 |

| 10 | 110 | 100 | OSH 10-100 | 15.7 | 157 | 200 | 4.7 |

| 20 | 231 | 50 | OSH 20-50 | 33 | 165 | 155 | 8 |

| 20 | 231 | 100 | OSH 20-100 | 33 | 330 | 205 | 10.5 |

| 20 | 231 | 150 | OSH 20-150 | 33 | 495 | 255 | 12.5 |

| 30 | 298 | 50 | OSH 30-50 | 42.6 | 213 | 175 | 10.5 |

| 30 | 298 | 75 | OSH 30-75 | 42.6 | 320 | 200 | 11.5 |

| 30 | 298 | 100 | OSH 30-100 | 42.6 | 426 | 225 | 12.5 |

| 30 | 298 | 150 | OSH 30-150 | 42.6 | 639 | 275 | 14.5 |

| 50 | 550 | 75 | OSH 50-75 | 78.5 | 589 | 210 | 21 |

| 50 | 550 | 100 | OSH 50-100 | 78.5 | 785 | 235 | 22 |

| 60 | 605 | 75 | OSH 60-75 | 86.4 | 648 | 225 | 26 |

| 60 | 605 | 100 | OSH 60-100 | 86.4 | 864 | 250 | 28.5 |

| 60 | 605 | 150 | OSH 60-150 | 86.4 | 1296 | 300 | 33 |

| 100 | 990 | 75 | OSH 100-75 | 141.4 | 1060 | 245 | 45 |

| 100 | 990 | 100 | OSH 100-100 | 141.4 | 1414 | 270 | 48.5 |

Features of Hollow Ram Jacks Single Acting

Different models of single-acting hollow ram jacks are available in the market, depending on their capacity, stroke length, working pressure, and design features. Some standard features of single acting hollow ram jacks are:

Plain ram: It means that the piston rod has a smooth surface without any threads or attachments. Plain ram jacks are suitable for applications that do not require precise alignment or attachment of accessories.

Collar threads: These are threads on the outer surface of the cylinder body that allows for easy mounting of accessories such as eye nuts or clevises.

Base mounting holes: These are holes on the bottom of the cylinder body that allows for secure bolting of the jack to a flat surface.

Stop ring: This metal ring prevents over-extension of the piston rod and protects it from damage.

Safety valve: This valve releases excess pressure in case of overload or malfunction.

Applications of Hollow Ram Jacks Single Acting

Hollow ram jacks single acting have many applications in various industries, such as construction, mining, bridge building, heavy lifting, tensioning, testing, and maintenance.

Some of the common uses of hollow ram jacks single acting are:

Post-tensioning

Hollow ram jacks single acting can be used to apply tension to steel cables or rods that are embedded in concrete structures, such as bridges, dams, or buildings. The wires or rods are passed through the hole of the jack and attached to a wedge or anchor at one end. The jack is then pressurized to pull the cable or rod and create a compressive force on the concrete. It increases the strength and durability of the structure.

Cable splicing

Hollow ram jacks single acting can splice or join two sections of steel cables or wires. The cables or wires are passed through the hole of the jack and secured with clamps or grips at both ends. The jack is then pressurized to pull the cables or wires together and create a tight connection.

Flange spreading: Hollow ram jacks single acting can be used to separate two bolted flanges. The flanges are metal rings that connect pipes, valves, or other equipment. The jack is inserted between the flanges and pressurized to push them apart. It allows for easy access to inspect, repair or replace the equipment.

Bolt tensioning

Hollow ram jacks single acting can apply tension to bolts that fasten two components together. The bolts are passed through the hole of the jack and secured with nuts at both ends. The jack is then pressurized to pull the bolts and create a clamping force on the components.

Shaft extraction

Hollow ram jacks single acting can extract shafts stuck in bearings, gears, or other machinery parts. The rods are passed through the hole of the jack and attached to a puller at one end. The jack is then pressurized to pull out (or push out)the shaft from its position.

Advantages of Hollow Ram Jacks Single Acting

Hollow ram jacks single acting have many advantages over conventional hydraulic cylinders, such as:

- They can perform both pushing and pulling operations with one device.

- They can accommodate different sizes and shapes of loads by passing them through the hole.

- They can reduce space requirements by eliminating external attachments or accessories.

- They can increase safety by avoiding side loads or bending stresses on the piston rod.

Orione Hollow Ram Jacks Single Acting has a capacity range from 10 to 200 tons and a stroke range from 50 to 300 mm. They have a maximum working pressure of 700 bar and come with collar threads, base mounting holes, a stop ring, a safety valve, a dust seal ring, a wiper seal ring, coupler half set with a dust cap.

Safety Precaution

Single acting hollow ram jacks are versatile tools that can be used for various industrial applications. However, they also require proper maintenance and safety precautions to ensure optimal performance and longevity.

Some tips for using single acting hollow ram jacks are:

Single acting hollow ram jacks are powerful devices that can help you accomplish various tasks easily. By choosing the suitable model for your needs and following proper guidelines, you can enjoy its benefits for years.

- Use only recommended hydraulic oil and keep it clean and contaminant-free.

- void side or eccentric loads on the piston rod as they can cause bending or damage.

- se accessories that match the jack's capacity and thread size.

- Do not exceed the jack's rated capacity or stroke length.

- Do not use damaged or worn-out parts or hoses.

- Follow the manufacturer's instructions for operation and storage.

Versatile Hydraulic Jack Design

The Hydraulic Hollow Ram Jacks Plain Ram models feature a hollow center plunger and a robust, single-acting structure. Their design accommodates versatile mounting options, including base and threaded collar mounting, and allows for both pressing and pulling operations. The external threads on the body simplify installation, while their compatibility with manual hydraulic pumps ensures controlled operation.

Enhanced Durability & Safety

Each Hydraulic Hollow Ram Jack is constructed from high-grade alloy steel with an anti-corrosive chrome finish, ensuring operational longevity, even in harsh work environments. Built-in safety valves and replaceable seals offer enhanced protection and maintenance efficiency, while compliance with DIN and ISO standards guarantees quality and reliability.

Wide Range of Applications

These hydraulic jacks excel in various heavy-duty uses such as maintenance, construction, heavy lifting, and testing. Their hollow centers accommodate threaded rods or cables, making them suitable for tensioning, pulling, and pushing. Accessories like couplers, dust caps, and pressure gauges further extend their utility in industrial tasks.

FAQ's of Hydraulic Hollow Ram Jacks Plain Ram, Single Acting:

Q: What applications can Hydraulic Hollow Ram Jacks Plain Ram be used for?

A: These jacks are ideal for pressing, pulling, testing, maintenance, construction, and heavy lifting. Their hollow center allows for tensioning operations involving threaded rods or cables, expanding their versatility across industrial sectors.Q: How does the spring return mechanism work in these hydraulic jacks?

A: The spring return mechanism enables the plunger to retract automatically once hydraulic pressure is released, ensuring safe and convenient operation without the need for external force or manual intervention.Q: When should I choose a specific stroke length or plunger diameter for my application?

A: Selection depends on your task requirements: longer stroke lengths (up to 150 mm) are suitable for deeper lifting or pressing, while larger plunger diameters (up to 60 mm) provide higher strength and stability for heavy loads.Q: Where can these jacks be mounted?

A: Hydraulic Hollow Ram Jacks offer flexible mounting options, including base mount and threaded collar mount. The external thread provided on the jack body makes installation straightforward onto machinery or workstations.Q: What safety features are built into the jack design?

A: Each jack incorporates a built-in safety valve to prevent hydraulic overloads, high-pressure seals to avoid leakage, and precision machined parts for reliable performance. These features work together to uphold operator safety and prevent equipment failure.Q: How do I maintain the hydraulic jack for optimal performance?

A: Regularly inspect and replace the high-pressure seals and dust caps as needed, ensure the chrome finish remains intact, and operate the jack within the recommended temperature range and pressure limits to maximize efficiency and lifespan.Q: What benefits do these jacks offer over traditional solid ram models?

A: The hollow plunger design provides a strategic advantage for tasks requiring threading, tensioning, or cable pulling, making these jacks more adaptable to complex applications compared to conventional solid ram cylinders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry